Drive rolls are crucial components in semi-auto welding (like MIG/MAG welding). They are essentially geared wheels that grip the welding wire and pull it from the spool, feeding it consistently through the welding gun and into the weld puddle.

Drive rolls have a strong relationship with welding wires. The size and type of welding wire directly dictate the drive roll you should choose. Using the proper drive rolls and tension is essential to ensure the wire feeds at a steady rate. This also prevents common problems like “bird-nesting” (a tangled mess of wire), wire slippage, or deformation of the wire.

目录

切换Three Types of Welding Drive Rolls

“U”, “V”, and “V-Knurled” Drive Rolls are primarily distinguished by their groove shape and surface texture. These characteristics are specifically designed to accommodate different types of welding wire.

V-Groove Drive Rolls:

- Description: These have a V-shaped groove and a smooth surface.

- Purpose: Used for hard solid wires like steel and stainless steel. The V-groove provides good grip without damaging the wire’s copper coating.

- Why they work: Solid wires are stiff, so they feed well with less aggressive gripping. V-groove drive rolls provide a secure “pinch” without distorting the wire, ensuring consistent feeding.

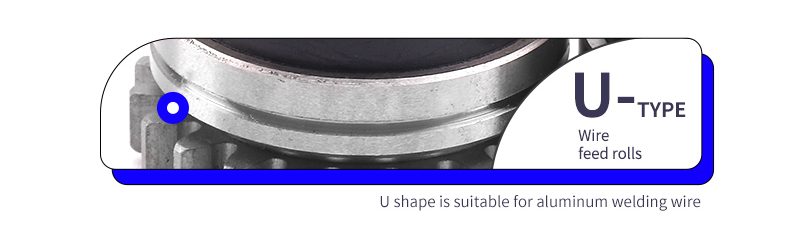

U-Groove Drive Rolls:

- Description: These have a U-shaped groove and a smooth surface.

- Purpose: Designed for soft solid wires, primarily aluminum.

- Why they work: Aluminum wires are very soft and prone to deformation or “mashing.” The U-groove cradles the wire, maintaining its round shape and preventing damage, while still providing enough friction for feeding. They also allow for a controlled amount of slippage to prevent bird-nesting.

V-Knurled Drive Rolls (or Knurled V-Groove/F-groove):

- Description: These have a V-shaped groove with teeth (knurling) on the surface.

- Purpose: Used for flux-cored wires (both gas-shielded and self-shielded) and metal-cored wires.

- Why they work: Flux-cored wires are softer due to their tubular design and internal flux, and often have a surface lubricant. The teeth “dig in” to the wire, providing extra grip to feed them consistently and prevent slippage, which can be an issue with these wires.

Drive Roll Materials

While steel drive rolls are common, other materials are also used, each suited for specific wire types. For instance, aluminum drive rolls are ideal for softer, annealed aluminum wire, as they help prevent deformation. Some very flexible wires, like silicon bronze, might even utilize plastic drive rolls for gentler feeding. The choice of material ensures optimal grip and prevents damage to the welding wire.

Here are some drive rolls made of different materials.

FAQs about Drive Rolls

Q: Can I use a V-knurled drive roll for solid wire?

A: While it’s generally not recommended to use V-knurled drive rolls with solid wire, if you must, the key is to use minimal spring pressure on the upper pressure roll of the wire drive system. Apply only the lowest amount of pressure necessary to ensure consistent wire feeding. Using too much pressure can damage the solid wire and clog your liner.